CNC Turning

TURNING PARTS - CNC TURNING PROCESS

WHAT IS CNC TURNING ?

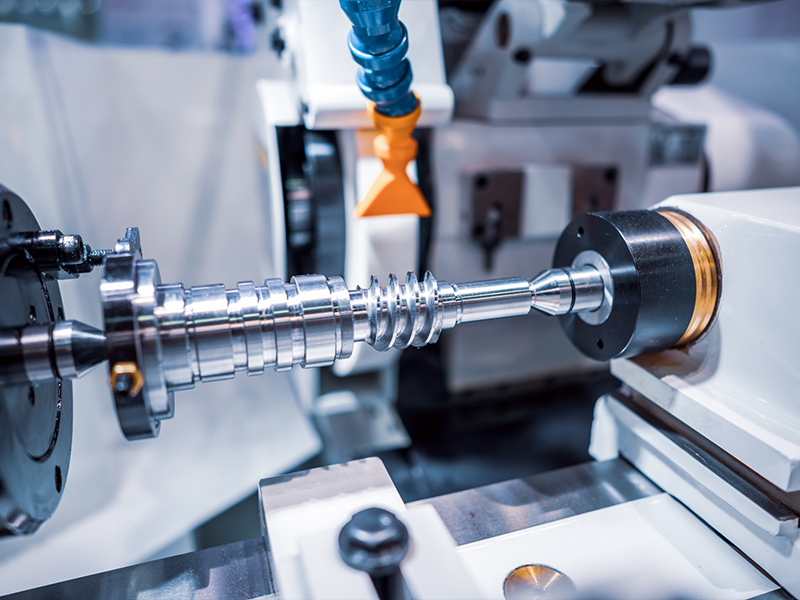

CNC turning is a highly efficient and precise manufacturing process among CNC machining. Using the technique of computer numerical control (CNC), the cutting tool is controlled to cut the material from the rotating workpiecce . Through CNC turning, we are able to make precision parts with high accuracy and effeciency.

Among the machining process, CNC turning is mainly used for the cutting of inner and outer cylindrical shaped parts, such as shafts, inner and outer conical surfaces with arbitrary cone angles, complex rotating inner and outer curved surfaces, cylinders, and conical threads. It can also perform grooving, drilling and boring etc.

Traditional mechanical processing is performed by manual operation of ordinary machine tools. During processing, the mechanical tool is shaken by hand to cut metal, and the accuracy of the product is measured by tools such as eyes and calipers. Compared with traditional lathes, CNC turning are more suitable for turning revolving parts with the following requirements and characteristics:

-

Phone

-

E-mail

-

Top